Flir Infrared Training Center (ITC) –Level 1 & 2 Certified Preventive Maintenance Infrared Thermal Imaging Survey, Inspection;Thermography - Infrared (IR) Thermographic Investigation, Scanning, Testing, Consulting and reporting services for:

- Electrical Systems & Equipment

- Mechanical & Rotating Equipment

- Home & Building/Radiant Heating

- PRE-COMMISSIONING, BASELINE & WARRANTY SCANNING

Our services are available in Canada, including the Metro Vancouver, BC; Edmonton, Calgary, Alberta; Whitehorse, Yukon Territory. In the Beautiful British Columbia, we serve Vancouver, Burnaby, New Westminster, Surrey, Richmond, Coquitlam, Langley, Abbotsford, Port Coquitlam, Port Moody, Delta and more.

The company does not have a ‘vested interest’ in finding an extra problem or sales opportunities after testing and inspections. It is totally up to the customers what to do next with our reports and recommendations. However; if you are not sure or have visible building, home, electrical /mechanical equipment or other systems problems, and you do not wish to deal with various trade contractors contact us. For your peace of mind, we can offer you Aitur Group Ltd “One Stop Shop” Infrared Thermal Imaging inspection, Survey/Testing Solution, including the full service circle.

Aitur Group Ltd “One Stop Shop” Solution Read more……

Client Benefits - Infrared/Thermal Imaging Hiding Deficiency Detection

- Non-contact, non-destructive, quick scan, problem identification, visualizes and analyze without interrupting service.

- Instant identification of heat/cooling losses, water leakage, missing/damaged insulation, flat roof leakage, mold in buildings, facilities, plants, condos and etc.

- Quick detection of cooling losses, insulation leaks in the refrigeration equipment.

- Quick identification of electrical/mechanical and other system deficiencies.

- Reduced unnecessary preventive maintenance and troubleshooting time.

- Prioritized corrective actions, improved preventive & predictive maintenance.

- Documented the identified problems before warranty/workmanship guaranty expire.

- Reduced equipment downtime; reduced cost of maintenance repairs or replacement.

- Improved the safety of staffs and business properties.

- Excellent tool for pre-purchase inspections and price negotiation.

- Help investors to protect their investment, avoid extra expenses& problems in future.

What is a Thermal Imaging Inspection/Survey, and How Does it Work?

The Thermal Imaging Inspection/Survey is a non-contact, non-destructive and quick testing method. The Thermal imaging Inspection, Infrared Testing allows us to scan, visualize and analyze temperatures of any object from the small residential to large commercial, industrial building, electrical &mechanical equipment or systems quickly and accurately.

The Infrared (IR) Scanning, Testing &Inspection, Thermal Imaging Survey is the perfect tool for building, commercial and industrial equipment preventive/predictive maintenance services.

Infrared thermography, photography, thermal imaging, and thermal video are examples of infrared imaging science. Thermography has a long history, although its use has increased dramatically with the power transmission, distribution, utility, commercial and industrial applications. Everything you see around you (objects), be it electrical/mechanical equipment, power lines, substations, heater, cold storage, fridge even wall, car, wood, (everything) has a certain temperature and they all emit waves of energy called ‘Infrared radiation’ (IR). The hotter the object is, the more energy it emits. A thermal imaging camera translates this energy waves into a viewable image, which shows a “heat picture” of the object the camera is pointing towards at the time. The actual detector we use within our thermal imaging cameras are somewhat similar to the human eye, and are very (hundred times) more sensitive.

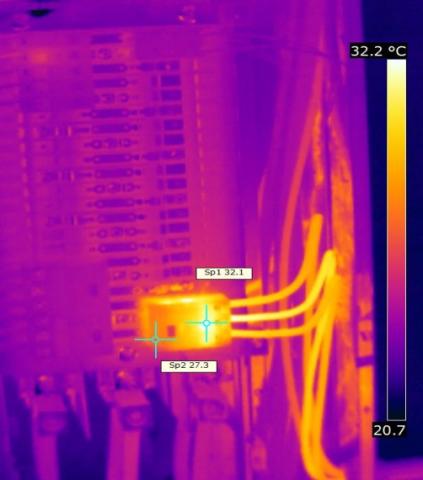

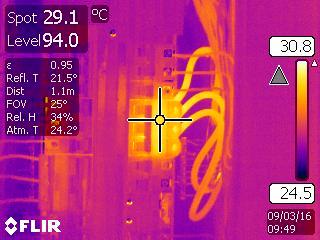

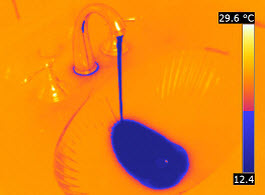

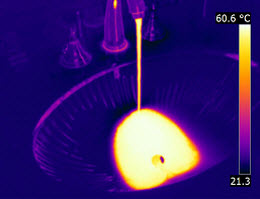

These Aitur Group‘s pictures below are simple examples of IR images.

Running cold water DC image Running cold water IR image.

Running hot water DC image Running hot water IR image.

On these pictures, a hotter object is shown as yellow white and a cooler object shows as dark blue. This is the basic concept of infrared imaging science. A thermal imaging/infrared camera can only detect/identify the temperature difference on any given surface. Thermal imaging/infrared camera cannot see through solid materials like drywall, plaster, concrete, steel, wood, doors and etc.

Application areas of thermal imaging technology are almost unlimited. We cannot list all the applications.

Contact us to book your inspection today!